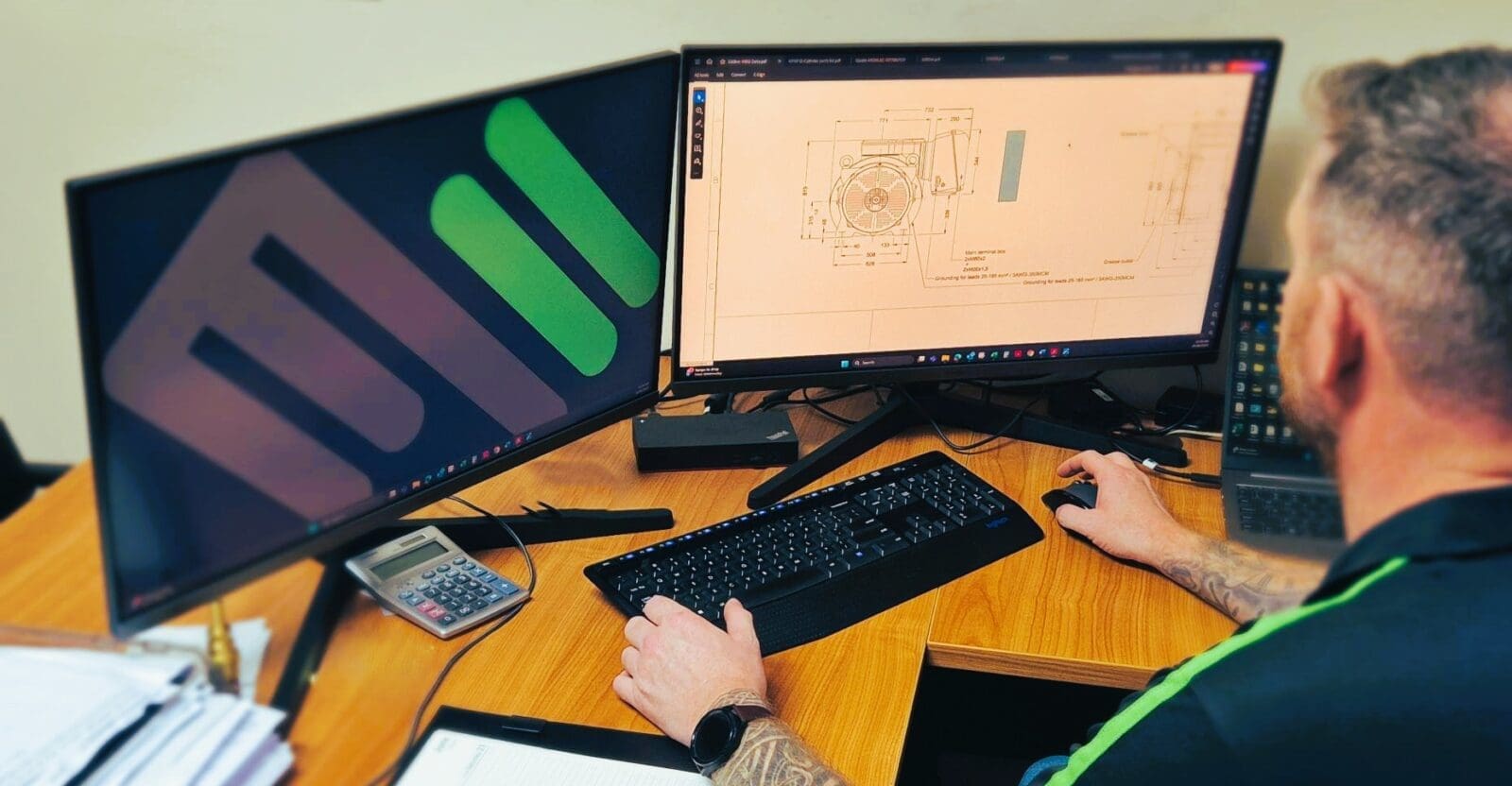

Since 1993, Morlec has offered a wide range of maintenance, laser alignment, sales, overhauls, and refurbishment services. With our extensive industry expertise and capabilities, we have consistently demonstrated our ability to provide tailored solutions via refurbishment, modification, or replacement.

We manage every phase of the process, from assessment and scope through to providing the most cost-effective solutions, with a focus on transparency and collaboration. Our services are provided across Australia to various organisations and businesses needing maintenance, refurbishment, installation, commissioning, and electrical work.

Morlec Electrical has years of proven industry experience. Our qualified team performs bespoke and market-leading services of the highest quality. Our services include

- Electric motor sales

- Electric motor servicing, overhauls and refurbishment

- Electric motor testing

- Electric motor rewinding, fractional horsepower up to 500HP

- Onsite motor mechanical repairs and laser shaft alignment

- Semi-hermetic stator rewinds

- Full electric motor repair workshop facility

- AC and DC motor repairs

- Single- and three-phase motor repairs

- Shaft earthing for VSD application

- New motor modifications for mining and other special applications

- Commercial centrifugal pump repairs, overhauls and sales, including Davey, Franklin, Regent, Flygt, KSB Ajax, PAX, and Tyco Southern Cross

To achieve our clients’ motor solutions, Morlec provides our clients with access to a variety of motor manufacturing providers, such as:

With such a diverse range of manufacturers and product options, Morlec aims to provide our customers with quality products at competitive prices.

Servicing &

Refurbishment

Morlec’s workshop is fully equipped with a machine shop, painting booth, extensive motor and no-load pump testing, and in-house motor rewinding facilities.

Overhauling or refurbishing a pump or motor can be highly beneficial for several reasons, including

- restoring performance

- extending lifespan

- reducing downtime

- cost savings

- improving reliability

- enhancing efficiency

- meeting updated standards

- customising to new requirements

- reducing environmental impact.

Motors

- CEG

- Toshiba

- FASCO

- CMG

- TECO

- WEG

- Baldor

- Techtop

- TECO

- WEG

- Baldor

- Techtop

- Brooks Crompton

- Franklin

Pumps

- Hidrostal

- Xylem

- KSB

- Grundfo

- Sulzer

- Franklin

- Davey

- Ultraflow

- TT Pumps

- NOV

- Lowara

- Klargeste

- Mono

- Wilo

- BS

- DA

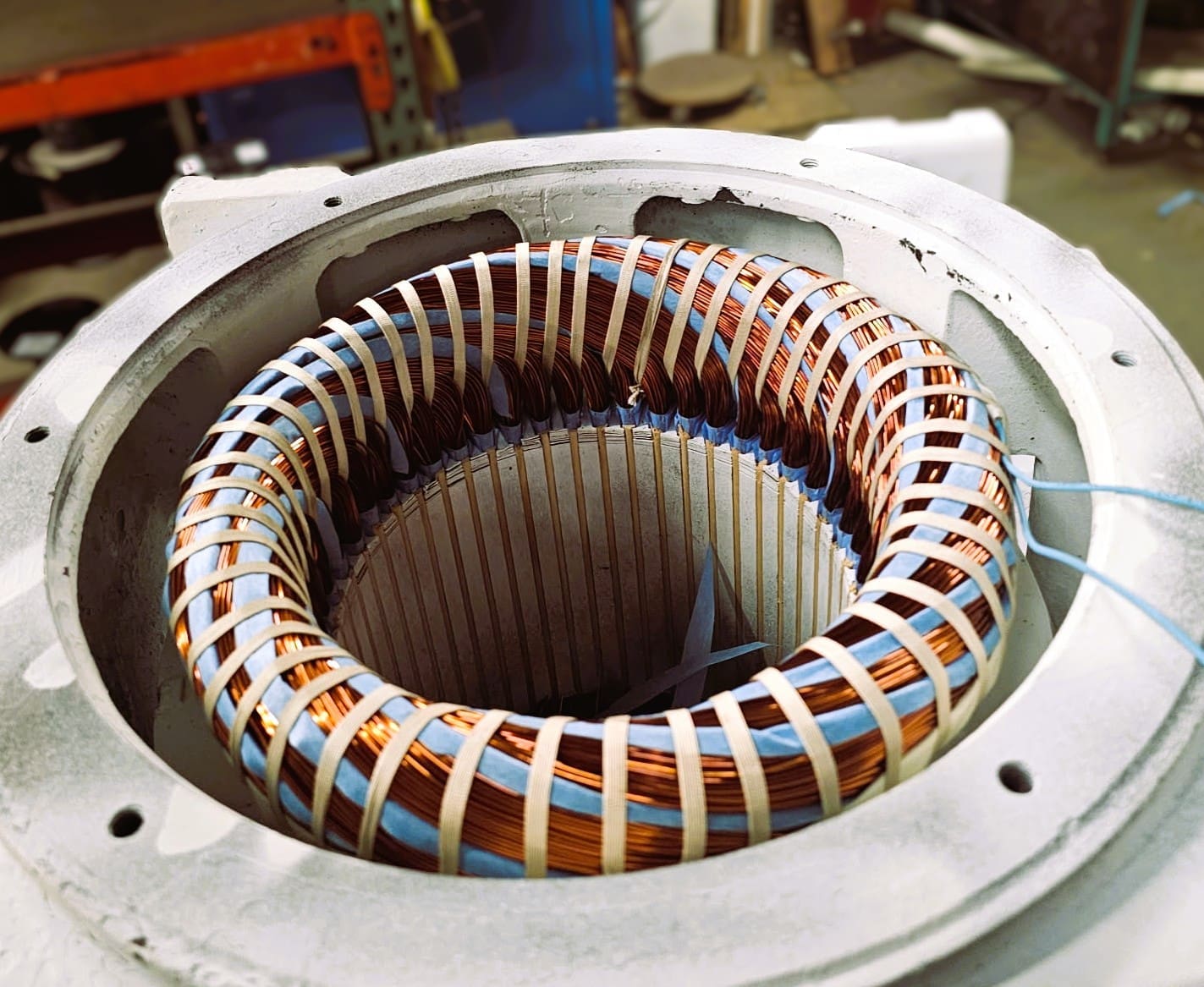

Rewinding

Motor rewinding involves replacing the wire coils in the stator or armature of an electric motor. Motor rewinding is often necessary when a motor fails or underperforms due to wear and tear. The benefits of rewinding a motor include:

- extended lifespan

- improved performance

- customisation

- sustainability

- reduced downtime

- enhanced reliability.

Motor Maintenance

Motor maintenance ensures electric motors’ reliability, efficiency, and longevity in various industrial, commercial, and residential applications. Motor maintenance is essential for several key reasons, including:

- reliability and availability

- extended lifespan

- energy efficiency

- safety

- compliance

- performance optimisation

- cost savings.

Laser Alignment

Pump and motor laser alignment is crucial for ensuring optimal performance, efficiency, and longevity of both components in various industrial and commercial applications. Benefits of laser alignment include:

- reduced wear and tear

- energy efficiency

- prevention of vibration

- enhanced performance

- maintenance cost saving

- enhanced safety

- compliance with standards.